Precision Planting

Plant precisely and purposefully, with Precision Planting

Simple technology to optimize your farming operation

Precision Planting technologies strive to position growers for maximum success across multiple planting variables: planting windows; seed depth and placement; consistent emergence; soil environment; fertilizer positioning; and planter performance. Adversity in the field, when met with smarter tools for farming operation, results in consistent and optimal yield across variable soil conditions, even with a hybrid crop. Plant precisely and purposefully, with Precision Planting.

Do more with what you have.

Unlock the untapped potential of your planter with upgrades and enhancements from Precision Planting’s line of products. Precision Planting brings new technology to existing implements, equipping your planter to operate smarter without needing to upgrade machines. Place seeds at precise depth and feed crops with precise subterranean fertilizer introduction as you move across variable fields, automatically adjusting along the way. Planting a hybrid mix this season? Precision Planting empowers you to adjust on the fly between hybrid seed, right in the field. Yes, perhaps “if it ain’t broke, don’t fix it,” but Precision has solutions for any grower to do what they’re doing already, but better.

-

VSET

Every 1% Loss in Singulation Costs You up to 2.5 Bu/A**

Meter performance is a key contributor to yield. If your meters perform at less than 99% singulation, you are losing out on yield. Walk your fields and measure off 17’ 5” of one of your 30” rows. Is there one skip? Is there a double? Are there more? Can you afford that at today’s grain prices?

**vDrive required. -

VDRIVE

Reduce Complexity

Today’s standard drive systems are complex, made up of 138* parts that must work together perfectly to position your seed for success. Even with a well-maintained planter, every one of those parts in the system increases your risk of planting errors. Planting your crop is the most important thing you will do each year. You’ve picked the right hybrids, the right population, and the right fertility plan. Do you want to risk all that on the performance of 138 interacting parts?

*Based on 16 row planter. -

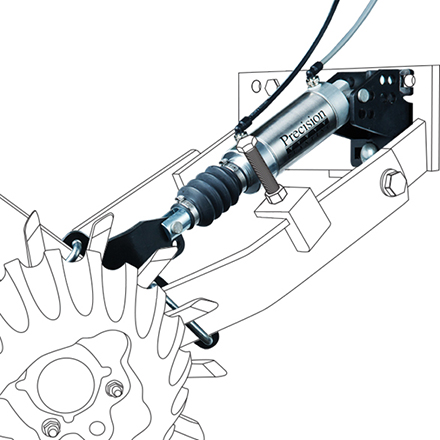

DELTAFORCE

Accurately Plant with Automatic Downforce Control

Planting conditions can vary from field to field, row to row, and on seed to seed. Is your planter equipped to get it right, every time? Yield potential is a variable you can take control and responsibility of with DeltaForce, replacing your planter’s springs or airbags with hydraulic cylinders and load cells to precisely measure carry weight on the row unit, making automatic downforce adjustments while you plant. As your planter empties, compaction decreases, and DeltaForce makes accurate adjustments to maintain consistency for maximized yield potential. -

CLEANSWEEP

Give Every Seed a Chance

CleanSweep enables remote row cleaner adjustments via controls housed inside the cab. CleanSweep makes adjusting on the fly easy, helping prevent late emergency from heat and moisture loss, and various seedling diseases, as well as ensuring nutrients are sown in your field rather than trapped in residue. CleanSweep leverages air cylinders on each row cleaner, controlled in-cab to fine-tune your planter’s row cleaner settings. -

VAPPLYHD

Eliminate Row-by-Row Variability

Many growers today understand traditional liquid application hardware lacks even distribution across the field. However, they may fail to realize their current system could have 15-30% row-by-row variation of the application. This variation creates hidden hunger (invisible deficiency) or over application, both impacting farm profitability. Do you know how much product is being applied on each row of your equipment? vApplyHD removes the guesswork with a measurement and control device on every row to fine-tune your operation. -

SPEEDTUBE

Maximum Speed with Optimal Yield

SpeedTube complements mSet and vSet technology to plant more acres an hour accurately and quickly with the same planter, without sacrificing performance or yield potential. SpeedTube utilizes two feed wheels pulling from the vSet disk and placing into the seed trench in a controlled rhythm. By eliminating bounce in the tube, seed release synchronizes with ground speed, so you plant quicker, better. -

MSET

Maximize Hybrid Plant Fields

The mSet system, when paired with vSet and SpeedTubes, enables growers to choose what suits their needs: maximize the potential of diverse-condition fields at a traditional speed, or optimize genetics and efficiency by pairing multi-hybrid planting with a high speed of execution. mSet empowers growers to capitalize on variability in their fields, allowing hybrid switching on the go, converting planting adversity into profitable diversity. -

CONCEAL

Fertilize Precisely

Why broadcast nitrogen on the soil’s surface when you’re planting below? Conceal trenches alongside your planting rhythm to introduce nitrogen closer to the seedbed, reducing fertilizer consumption by up to 30%, while maintaining yield. Fertilizing beneath the surface also eliminates most of the natural volatility, ensuring more of your fertilizer truly goes towards providing nutrients to your plants. When water is introduced into Conceal’s fertilizer trenches, your nutrients follow the soil profile, providing access to crown roots during growth.

QUESTIONS? CALL US TODAY! 1-605-777-7450

Interested in a quote or more information?

Interested in a quote or more information? Fill out the form to connect with our team or contact your nearest Butler location today 1-605-777-7450

"*" indicates required fields