6 Reasons to Choose Butler S.O.S. Services

If you don’t have a strong fluid analysis program or you’re sampling with another lab, here are six compelling reasons why Butler S.O.S Services beat the rest.

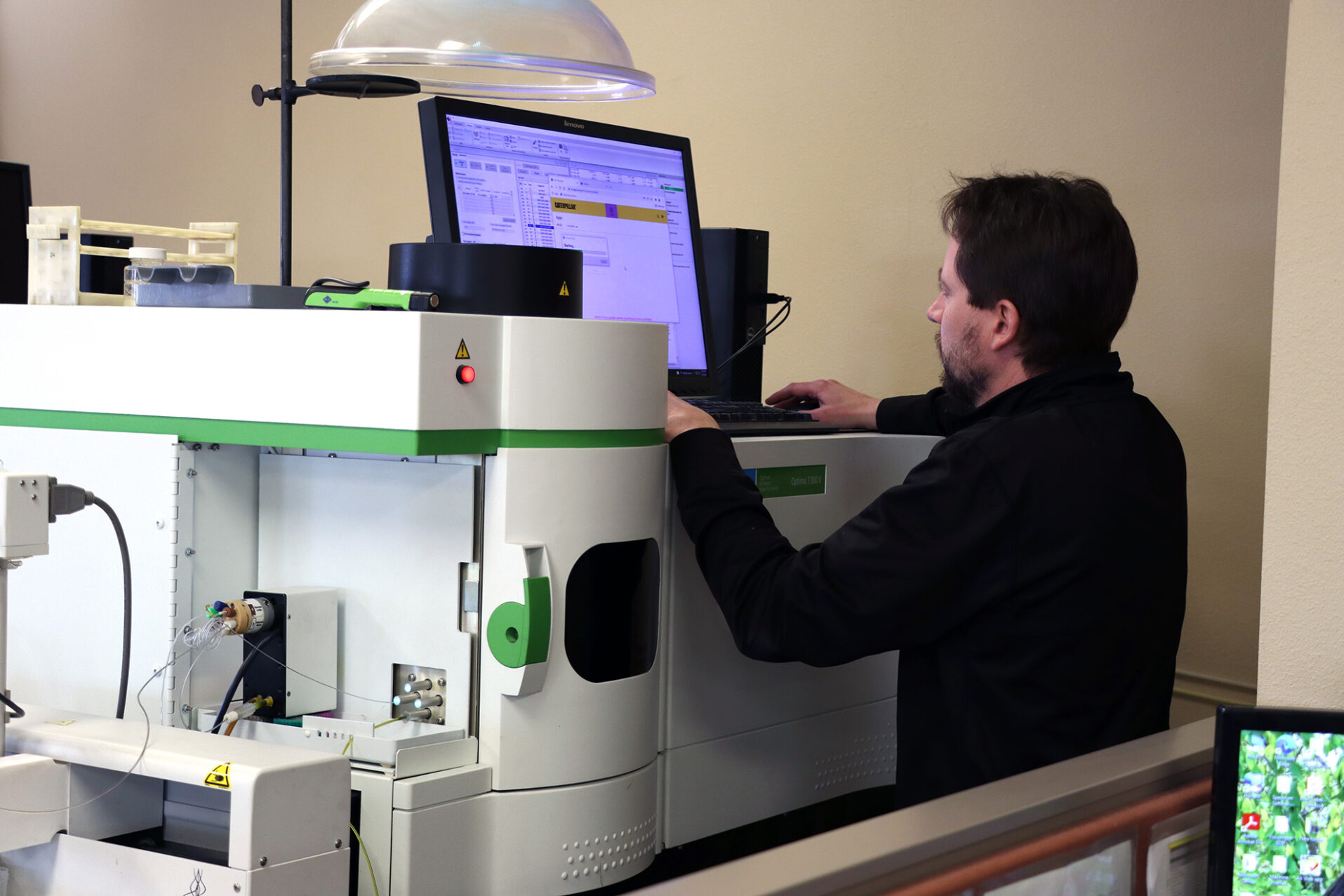

1. Get results you can trust

The S.O.S services process is built by Caterpillar scientists and backed by product engineers. Our worldwide testing standards ensure consistent quality, so you receive accurate, detailed results every time, with industry-leading turnaround times.

2. See sophisticated trend analysis

We evaluate your sample based upon complete product knowledge, fluid properties, and analysis of millions of data points—with more than 7 million samples tested each year.

3. Our experts care about your bottom line

Butler can set a sampling schedule tailored to your needs, and integrate it into a robust equipment management program. Not only will you save by fixing issues before failure, but you’ll also optimize operations to control your costs.

4. Enjoy complete condition knowledge

Your fluid data is integrated with other vital condition monitoring information—giving you insights into health, performance, location, and more. Using our global infrastructure, you can seamlessly sample with any lab and get a complete history.

5. Mixed fleet? We have you covered

Our team knows engines and components better than anyone, whether made by us or another manufacturer. In fact, about 25% of all samples come from equipment manufacturers. We’re your total solution for mixed fleets.

6. We’re built for every type of fluid & application

Butler handles oil, coolant, and diesel fuel sampling for all kinds of equipment, from construction, agriculture, power generation, pipeline, mining, and more.

Request information